Process Manufacturing ERP Features Designed to Meet Your Needs

With a comprehensive set of native capabilities that are critical to the business needs of batch and process manufacturers, Deacom ERP provides a level of Hyper-Tight Process Control™ that goes beyond typical ERP systems.

Minimize inventory handling and maximize your production output

Deacom's built-in supply chain planning tools can help you centrally manage critical manufacturing processes— from material requirements planning (MRP) to sales and production forecasting. This includes optimizing the use of manufacturing equipment, maximizing order-fill rates through inventory and production planning, and centralizing business intelligence reporting for purchasing and manufacturing planning.

Manage production, ensure quality, and track labor

Ensure the success of your business with manufacturing operations capabilities that include the planning, execution, and control of your manufacturing processes. By having these native to your ERP, you can be confident that you’re producing high-quality products that meet customer demand.

Enable strict process control within your warehouse

Streamline your manufacturing and distribution centers with real-time inventory management and warehousing features that drive scalable and repeatable business processes. Track best-before dates, batch numbers, quantities, and weights with GS1-128 barcodes, ensuring warehouse efficiency and proper lot tracking.

Manage sales orders, pricing rules, and financial reporting

Place sales orders, set up unique pricing models, and create inter-company transfers with real-time impacts on MRP and reporting. Access a multitude of financial reports beyond the classic balance sheets and profit/loss statements that you need to run your process manufacturing business.

A seamless user experience with a single login

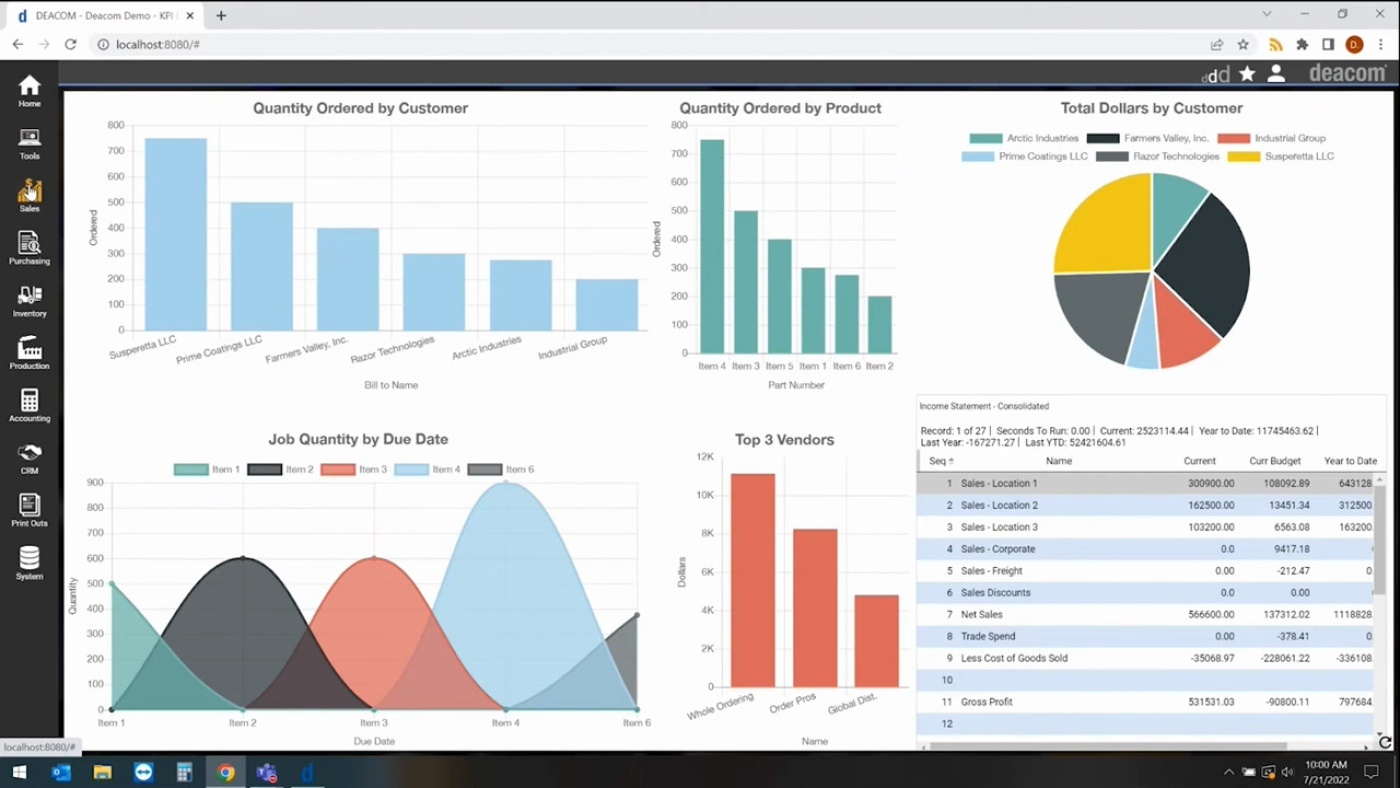

This video provides a brief overview of the user experience of Deacom's ERP software, showcasing various BI dashboards that are available to users. The video also demonstrates how users can drill down into specific source transactions and access different areas of the system that are relevant to their business processes, such as sales, purchasing, and inventory management.

Enforce quality control measures in every step of the process

With Deacom ERP software, you can implement configurable quality control checkpoints that span the entire product lifecycle, from formulation through shipment. QC tests are often incorporated into various business processes such as when raw materials are received on purchase orders, to finished goods produced on production jobs, and even when previously sold products are returned.

Generate documents that meet regulatory requirements

Leverage Deacom's document creation and management features to keep track of documents like vendor scorecards, item specifications, customer requirements, and signed BOL’s for sales orders. Food and beverage manufacturers can generate certificate of analysis and nutrition fact panels, while those manufacturers dealing in hazardous materials can ensure the proper Globally Harmonized System (GHS) Labels and Safety Data Sheets (SDSs) are created for their finished goods.

Implement a seamless user experience with a single login

No matter which part of the system your team is using, they only need to worry about logging into one system and working within one interface. Watch this video to get a brief overview of our Deacom ERP user experience and see various BI dashboards that are available to users. The video also demonstrates how users can drill down into specific source transactions and access different areas of the system that are relevant to their business processes, such as sales, purchasing, and inventory management.

“With Deacom, we can take our inventory control to a specific shop location and relieve material used in a batch more efficiently than ever before.”

“When I look at the speed and efficiency with which our people do their jobs now with Deacom, the difference is night and day.”

“Partnering with Deacom has resulted in far more than we expected. They took the time to learn what our company needed and committed to delivering it.”