Deacom: Growth without losing control of operations, margins, or risk.

Grow your business without losing control

Deacom is the all-in-one ERP built for process manufacturers who need real-time visibility, predictable margins, and total confidence at every stage of scale.

- Protect your margins with live cost and profitability data for every batch.

- Scale multi-site operations on a single, unified cloud platform.

- Future-proof your company with software that grows as fast as you do.

Why Choose Deacom ERP for Process Manufacturing?

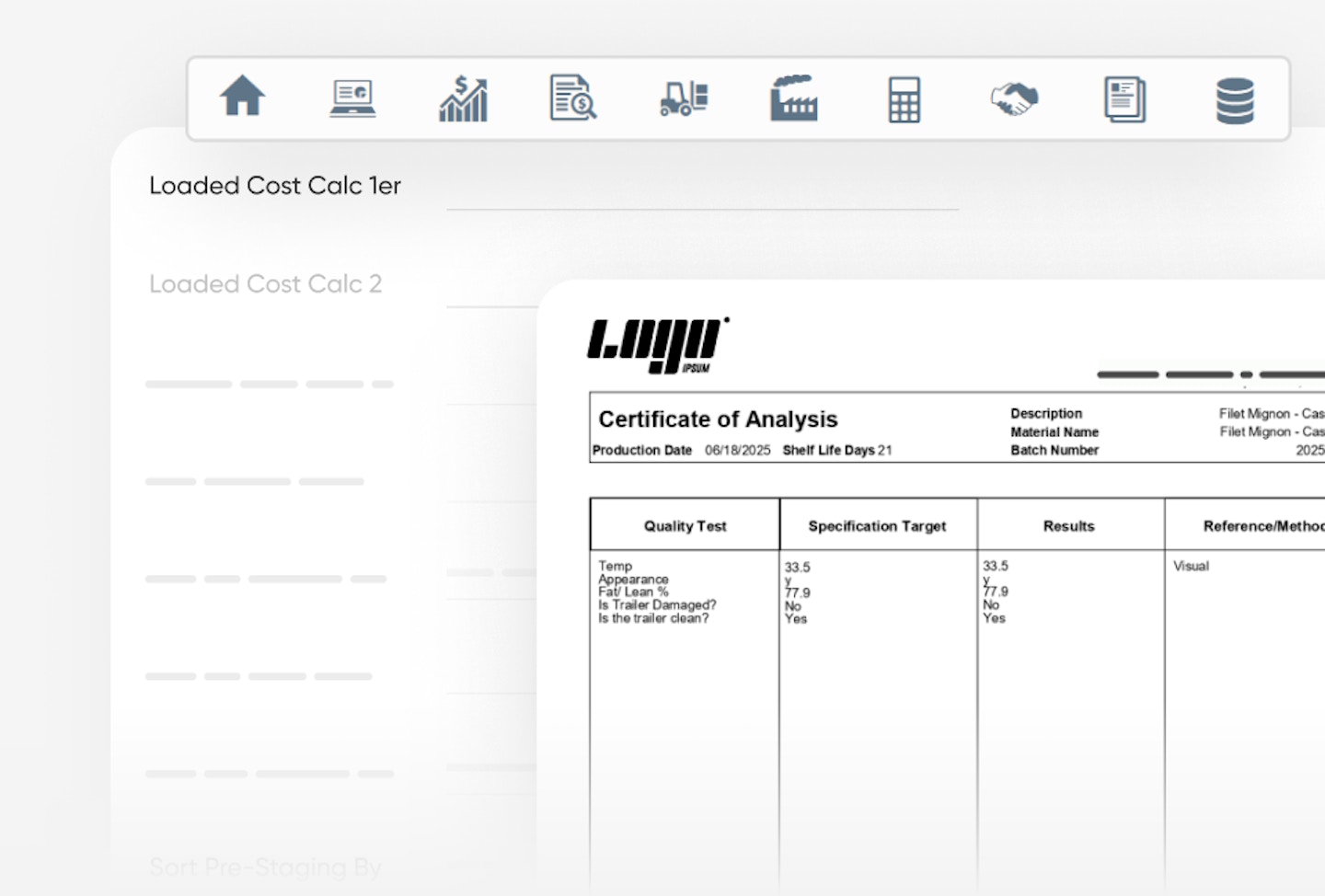

Ensure real-time batch quality

Enforce quality checks & collect real-time test data from the shop floor. Automate quality holds. No skipping steps or unauthorized changes.

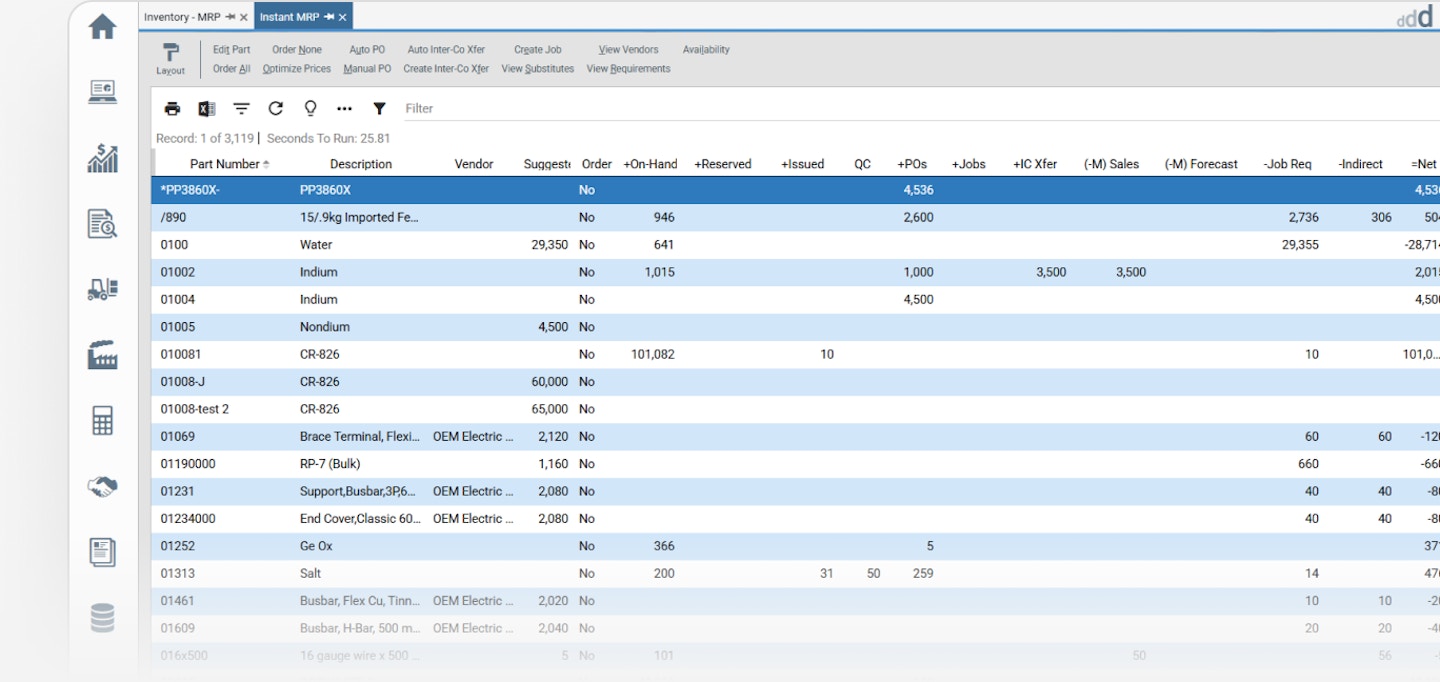

Gain inventory accuracy with forecast-driven replenishment

Calculate exact quantities of raw materials & finished goods. Based on inventory, forecasts, and schedules. Auto-reorder. Avoid shortages.

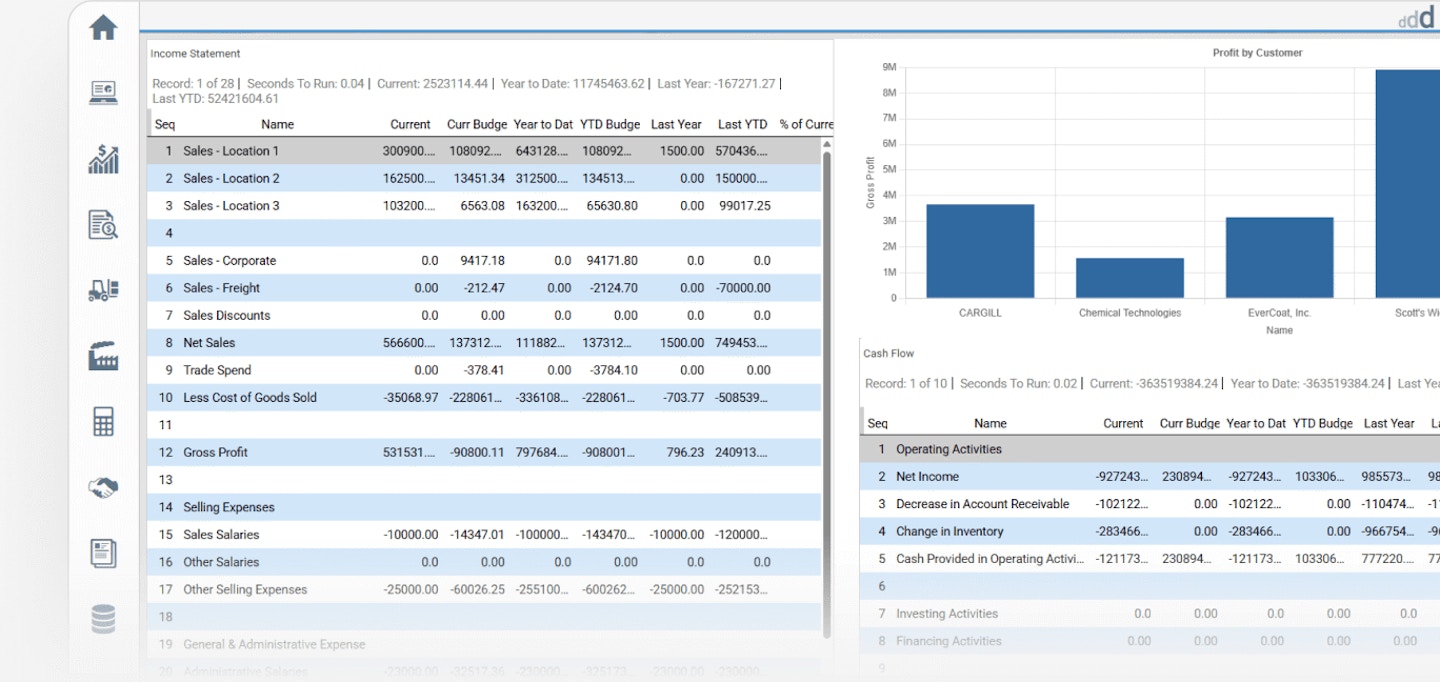

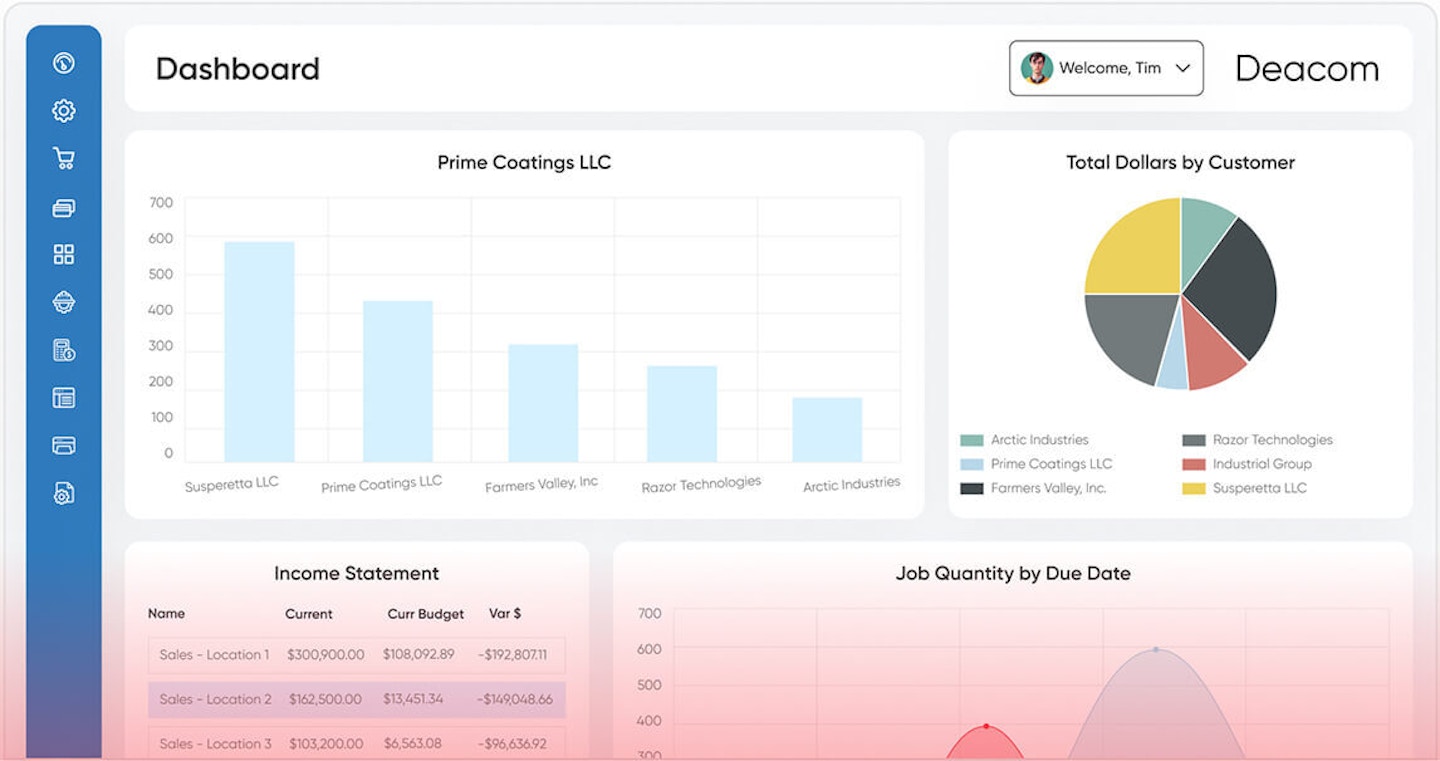

See production visibility & analytics at a glance

Run your business in real-time. Isolate time & materials waste. Full visibility into production, sales, financials, and more. Boost profits.

Optimize every step of manufacturing processes

Built-in process controls for manufacturing efficiency

Implement strict quality checks at every point. Manage formulas efficiently. Auto-calculate materials. Optimize production, finishing, shipping, and more.

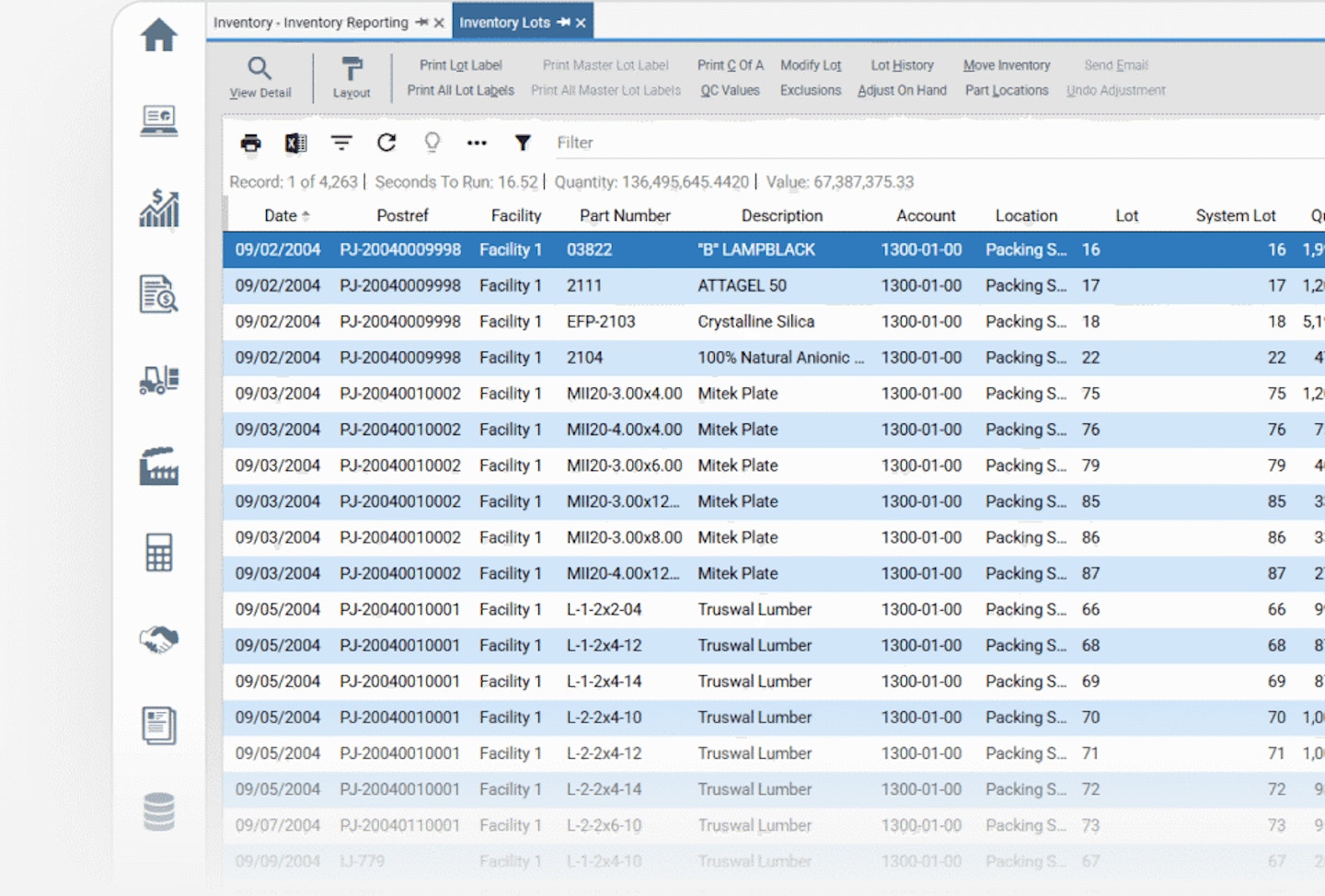

Traceability across materials & finished goods

Track raw & finished material lots across batches, finished products and shipments.

Built-in compliance for regulated manufacturing

Generate Certificate of Analysis and audit trails. Supports GMP, SQF, FDA, GHS, FSMA, and more.

Financial control across production, labor & shipping

Track costs, including raw materials, labor, overhead, and shipping. Calculate actuals vs standard costs. See where to cut costs & optimize processes.

Batch and process manufacturers using Deacom ERP

Deacom supports these process manufacturing industries

Spreadsheets, whiteboards, and manual updates slow ops and hide critical issues.

Unify scheduling, inventory, and compliance with a single real-time, no-code platform.

FAQ

What built-in tools are available to manage complexity?

Here are a few of the most used capabilities that Deacom provides to batch and process manufacturers:

- QC / CoA / Customer-Specific Requirements

- Lot Tracking / Recall Reporting

- Batch Record Enforcement

- EDI Trading Partner Compliance

- Regulatory Requirements (FDA, GHS, SQF, etc.)

- Job Costing

- Shelf-Life Adherence

- Supply Chain Management / Material Resource Planning

Can the ERP system help us manage our sales forecasts?

Yes. Deacom can help you predict sales based on historical data so you can more accurately project trends in your business. These forecasts can be used throughout the system but are very useful in MRP. Within the software, you can:

- Drive the purchase of long-lead-time raw materials based on sales forecasts

- Create forecasts for products based on historical sales

- Apply percentage-based changes to the forecast based on projected trends in the business

- Import customer-specific forecasts from Excel to ensure you have the production capacity to handle expected orders

What are the production capabilities of the ERP software?

Production is at the very core of most batch and process manufacturers. Deacom’s production capabilities include planning, scheduling, inputting, closing, and reporting on production jobs.

How do I track how materials are issued to jobs?

As part of the manufacturing process, it is critical to identify the precise lots that go into production from a raw material standpoint, as well as to document the finishes of a product with real-time visibility. Most of our customers perform these processes using scan guns and the Deacom Warehouse Management System (WMS).

How does Deacom help us calculate our material planning requirements?

One of the most important tools from a production planning perspective is the MRP (Material Requirements Planning) tool. Core MRP functions within Deacom help businesses:

- Reduce waste by maintaining the lowest possible material and product levels

- Gain full visibility on customer demand and supply of their inventory

- Optimize their supply chain management

- Plan manufacturing activities

- Manage delivery schedules

Can Deacom handle my customer’s specific quality control specifications?

Yes. Deacom provides an efficient way of making sure the correct products get to your customers, especially for those that require specific quality control specifications. You can manage QC specs including specific tests, target values, and min/max values of acceptance for the finished product directly from within the software. This helps your warehouse pickers confidently identify which lots will meet those customer requirements.

Can Deacom help me with my lot tracking and traceability needs?

Yes. Deacom allows you to drill down into inventory reporting starting from the raw materials all the way to the finished goods and view the specifics of everywhere that a lot was used. Because the system is built upon a single database, full traceability is available throughout the entire formulation to shipment process.

What BI reporting is available to me?

The ability to generate reports quickly and efficiently is a significant benefit of using the Deacom ERP system. The built-in reporting tools are user-friendly, simple to set up and configure, and consistent throughout the software.

My manufacturing company has a need for environmental reporting. How can Deacom help me with that?

The Environmental Reporting feature in Deacom supports reporting requirements for emissions during production and hazardous contents of products shipped to customers. Included is the ability to run reports, generate GHS & SDS labels, and create regulatory-compliant BOMs.

We operate within an FDA-regulated industry. How can Deacom help us manage any potential recall reporting?

The effectiveness of recall management hinges on seamless traceability within your supply chain management. To support this need and conform to the FDA’s identification and traceability regulations for food manufacturers, Deacom’s ERP solution provides lot tracking, asset tracking, and serialization capabilities. This allows users to identify and trace material at each stage of the product lifecycle.

Optimize manufacturing workflows with cloud-based ERP software