Ridder iQ ERP Software for Manufacturing

The practical all-in-one ERP solution designed for manufacturing SMEs that streamlines every process

- Smarter production Plan and manage production in real time. Track materials, orders, projects, and capacity and increase delivery reliability.

- Cost & margin insight Monitor hours, materials, and pre/post-calculations in detail.

- Supply chain control Manage suppliers, purchase orders, and stock levels in one system. Strengthen collaboration across the chain and reduce lead times.

Join top manufacturers streamlining operations with Ridder iQ

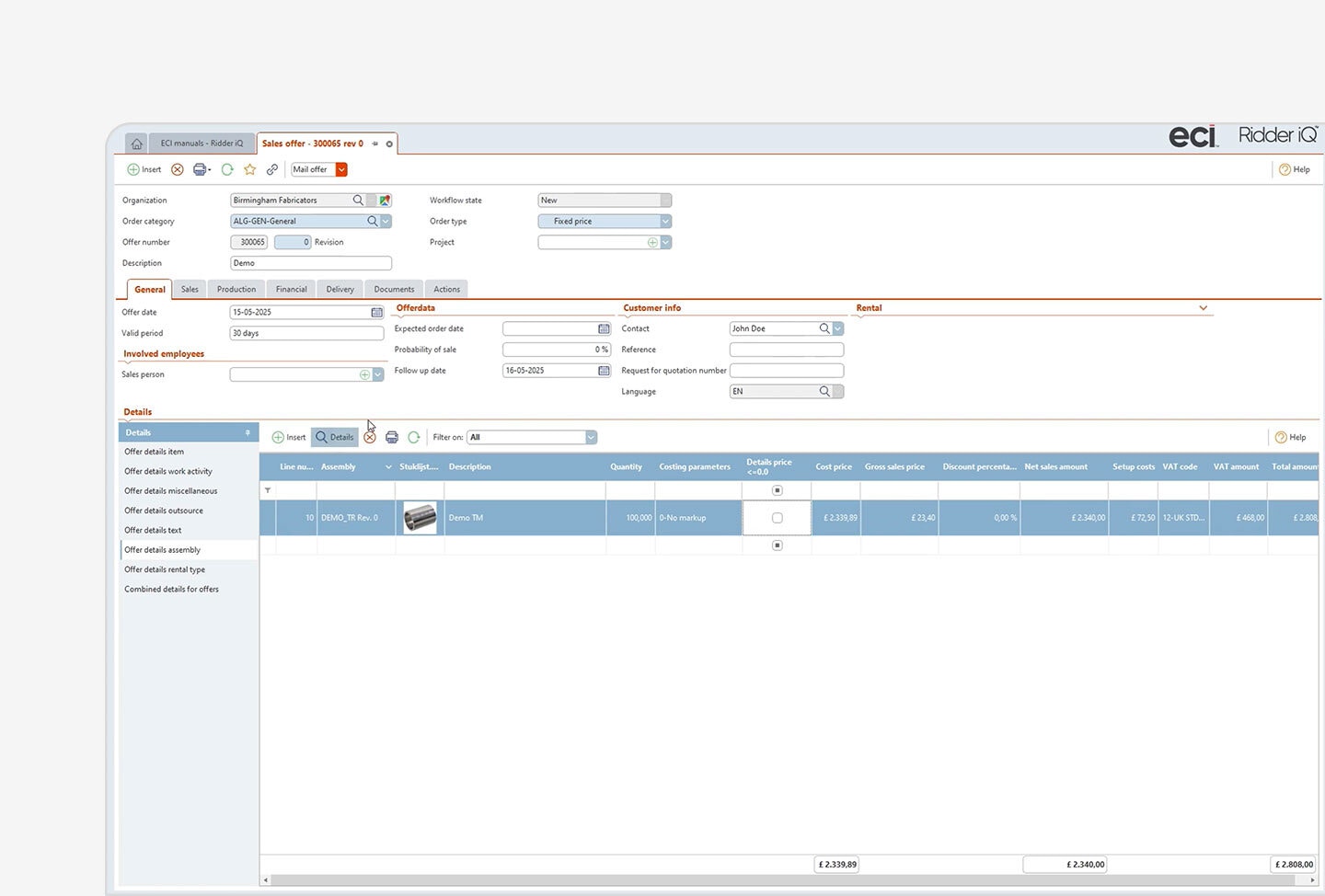

Streamline project & order management

Manage all discrete manufacturing processes. From quotation to delivery, keep control of deadlines, resources, and costs with full end-to-end visibility.

Prevent costly inventory issues

Manage raw materials, components, and finished goods with precision. Align stock with planning and forecasts, automate reorders, and avoid shortages or excess inventory.

Gain full business insight

Monitor your entire operation in real time. Identify work in progress, materials, and all production processes. Get clear visibility into production, projects, sales, and financials to improve margins and drive growth.

Optimise every step of manufacturing processes

Efficient Bill of Materials management

Create and manage multi-level BOMs with CAD/PDM integration. Avoid duplicates, auto-calculate materials, ensure version control, and optimize assembly, production, and delivery without errors.

Deep traceability

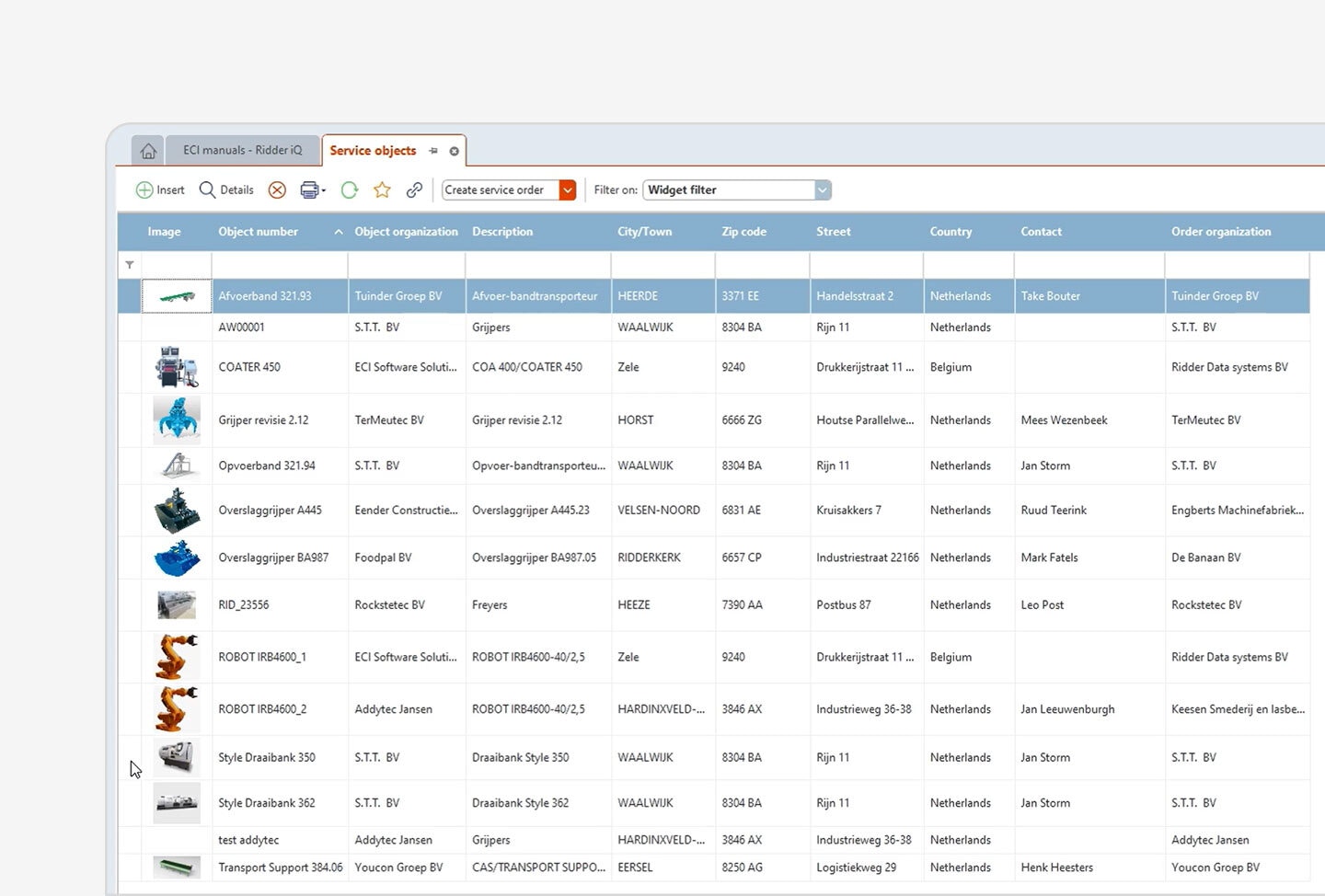

Track raw & finished material lots across batches, finished products and shipments.

Smart document management

Centralize technical documentation such as drawings, certificates, and work instructions. Ensure the right information is always available.

Costing & financial control

Perform detailed pre- and post-calculations for projects or orders. Track material, labor, and overhead costs, compare planned versus actual results, gain margin insights, improve quoting accuracy, and strengthen financial performance.

Industries

Join over 1300 manufacturers who are maximising profitability by integrating every production process in one system with Ridder iQ ERP

Manual scheduling, stockouts, and blind spots stall production and drain resources.

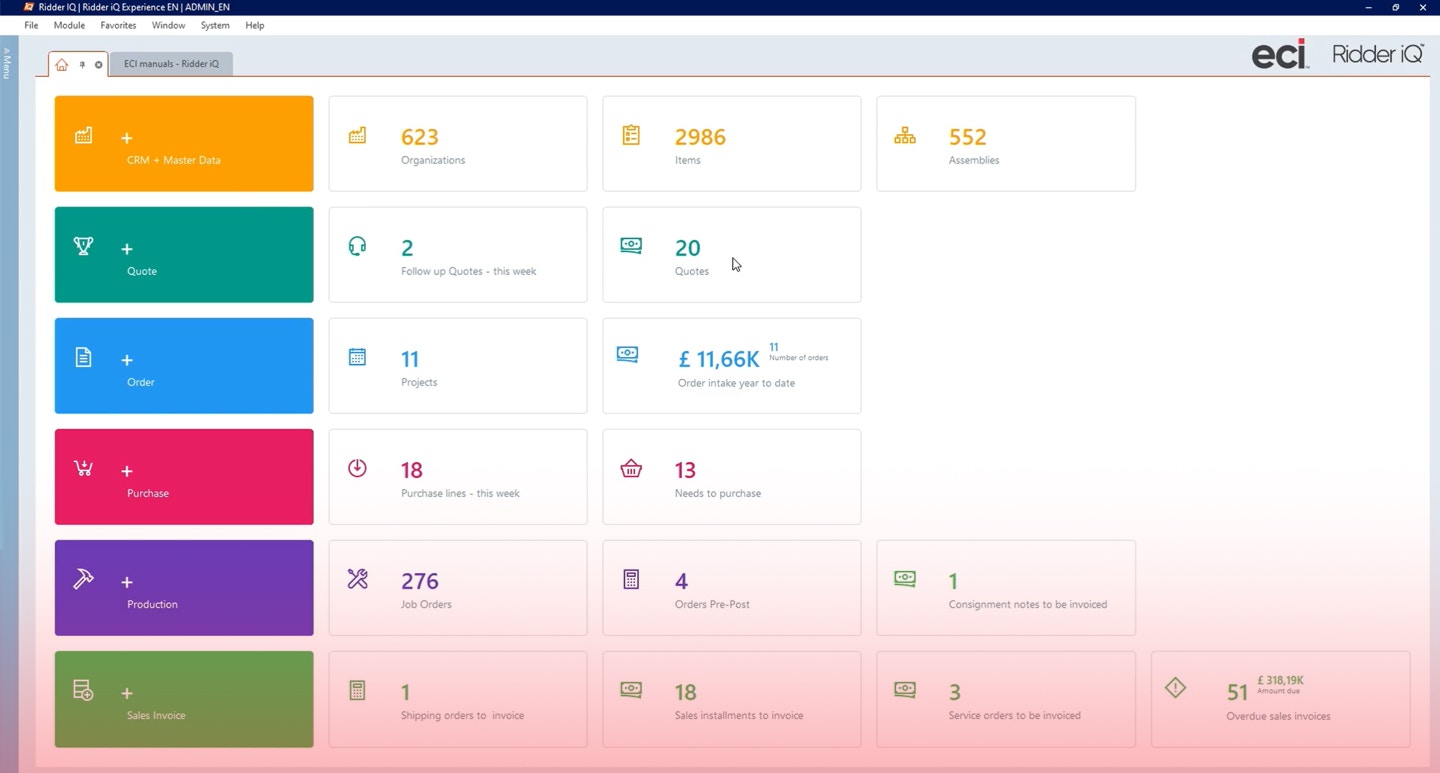

See everything - scheduling, inventory, and job tracking - all from one smart dashboard.

FAQ

What are the main functionalities of Ridder iQ?

Ridder iQ ERP offers functionalities such as CRM, costing, bill of materials, work preparation, purchasing administration, inventory management, production planning, time/personnel administration, document management, financial administration, and extensive reporting capabilities. Everything is integrated into one system for optimal efficiency.

For which type of companies is Ridder iQ suitable?

Ridder iQ ERP is specifically designed and developed for the manufacturing industry, targeting production and engineering companies within the SME segment. Its flexibility and scalability allow it to adapt to your specific business needs.

How does the implementation of Ridder iQ proceed in my company?

The implementation of ridder iQ follows a proven, step-by-step process from initial analysis to final training. whether you are migrating from an existing system or adopting ERP for the first time, we support you from start to finish to ensure a seamless transition.

Which integrations does Ridder iQ support with other software?

Ridder iQ integrates seamlessly with various in-house & third-party software packages such as accounting programs, CAD software, and e-commerce platforms. This ensures streamlined data exchange and more efficient workflows.

What support and training does Ridder iQ offer?

How is data security arranged in Ridder iQ?

Your data security is our absolute priority. Ridder iQ is fortified with advanced encryption and automated backups to ensure your business-critical information is always protected. with granular access controls, you maintain total oversight of who sees what, ensuring your data remains secure

Streamline all your manufacturing workflows