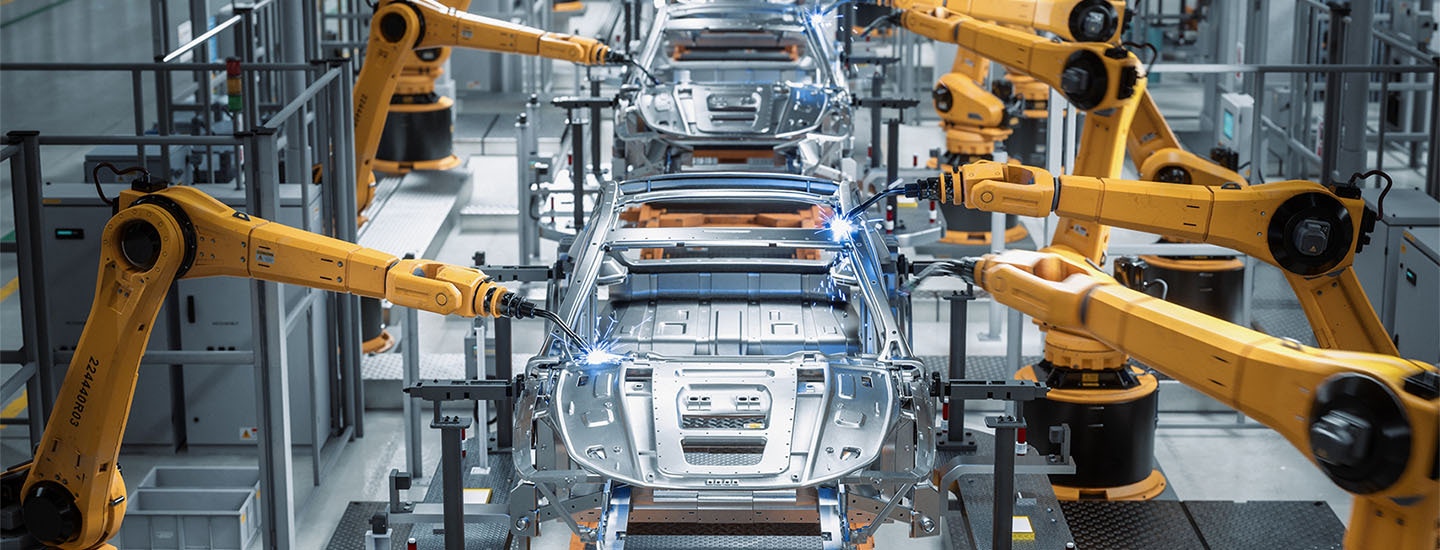

Automotive Manufacturing ERP Software

Industry Challenges in Automotive Manufacturing

Heavy truck manufacturing and motor vehicle parts and accessories manufacturing remains an increasingly competitive industry with over 1,100 manufacturers and revenue expected to reach approximately $4.7 billion in 2025.

Managing Complex Supply Chains

Global unpredictability of supply chains is making it harder than ever for automotive manufacturers to remain competitive. Fluctuating production costs make inventory management extremely important to maintain production processes for profitability.

Ensuring Quality & Compliance

Manufacturing ERP software is vital for quality and compliance because it embeds quality control directly into production processes, providing real-time monitoring, alerts for deviations, and traceability for quick identification of issues. To ensure compliance, your ERP needs to streamline reporting, enforce industry standard workflows, minimise errors and ensuring consistent quality while mitigating risks.

Improving Time-to-Market

ERP software designed for top tiered suppliers is crucial for speeding up automotive processes by integrating and optimising key business functions. Quickly generate Bills of Materials (BOMs) and production schedules for faster production. Improve demand forecasting accuracy and optimise automotive inventory to ensure parts are available when needed. Real-time visibility on the shop floor, eliminates delays and bottlenecks.

Adapting to EV & Sustainability Demands

According to the Electric Vehicle Council, new electric vehicle sales in Australia reached an all-time high in 2024, underscoring the sustained demand for cleaner, modern, cost-effective automotives. Data reveals that battery electric vehicle (BEV) and plug-in hybrid electric vehicle (PHEV) sales are only increasing every year. Should these increases continue, the automotive manufacturing industry demand for replacement parts, maintenance, and recycling of components will continue to see sustainable growth.

Core ERP Functionality for Automotive Industry

Automotive manufacturers operate with immense complexity, dealing with thousands of automotive parts, intricate assembly processes, global supply chains, and stringent quality demands. Small to medium manufacturers in the automotive industry need efficiency to deliver on their promises.

- Automotive Parts & Accessories Management: Robust parts management is imperative, especially during times of economic uncertainty. It's no longer just about tracking inventory; it's about building resilience, controlling costs, and maintaining productivity.

- Supply Chain Resilience: In an unpredictable global environment, strong parts management enables supplier diversification, enhances real-time visibility into parts, and facilitates contingency planning to navigate disruptions.

- Inventory & Warehouse Control: Effective parts management helps automotive companies explore alternative sourcing, and strategically manage inventory levels to absorb or pass on increased costs to customers. It provides the data to make informed pricing decisions.

- Real-Time Production Monitoring: A single missing part can halt an entire assembly line. Proactive industry parts management prevents costly production stoppages by ensuring critical components are always available.

- Recall & Traceability: Integrated ERP systems allow for powerful analysis to forecast needs, model the impact of tariffs, and make agile decisions on sourcing and pricing in volatile markets.

Tailored automotive ERP for continuous improvement.

Production Planning & Scheduling

Meet demand and cut costs in your shop floor operations. Manage intricate BOMs, optimise resources, and manage production schedules with ease.

Supply Chain Management

Reduce supply chain disruptions and oversee the entire flow of materials and goods across all manufacturing operations, ensuring timely component delivery to customers.

Inventory & Warehouse Management

Tracks and optimises the storage and movement of vast numbers of automotive parts, ensuring precise inventory levels for production and full traceability.

Quality Management

Ensures products meet evolving industry standards through real-time monitoring, defect tracking, and traceability for compliance and continuous business improvement.

Financial Management

Handles all financial operations, including complex cost accounting for varied product configurations, multi-currency transactions, and robust financial business reporting.

Sales & Operations Planning

Align sales forecasts with production capabilities and supply chain resources, balancing customer supply and demand.

Automotive Solutions for All Industry Segments

Our automotive manufacturing software is designed to provide deeper insights for small to medium manufacturers; addressing unique challenges across the diverse automotive value chain, optimising operations for each unique segment.

Tier 1 & Tier 2 Suppliers

An ERP is crucial for managing materials and components, streamlining production planning, and ensuring parts are delivered when and where they're needed. With enforced quality controls in product design and traceability for compliance, maintaining customer confidence is effortless.

Original Equipment Manufacturers

OEM's need an ERP as their central productivity system, managing processes from integrating design data to handling complex product assembly, production line equipment effectiveness and distribution. It's essential when managing thousands of components in real-time across multiple manufacturing plants.

Aftermarket Services

ERP software enhances the customer journey and service operations; eliminating data silos. Optimise inventory management, streamline services, and handle financials. This improves customer satisfaction, ensures parts availability, and boosts operational efficiency.

EV Battery Manufacturers

For EV battery manufacturers, ERP software provides support for unique production methods and helps improve quality and safety standards. Reliability to deliver to automotive OEM's in key to securing contracts and sustaining customer relationships.

Collaborate Across the Automotive Ecosystem

The central nervous system of an automotive manufacturer is their ERP. It transforms how departments collaborate with a "single source of truth" for all business data. Instead of disparate spreadsheets or departmental systems, every piece of data is entered once and becomes accessible to all authorised departments in real-time.

Enhance Operational Efficiency and Innovation

The key benefits of a single source of truth in the automotive industry:

- Eliminating Redundancy and Errors: Data is entered once, reducing duplicate efforts and manual errors that arise when information is re-entered or transferred between disparate systems.

- Automating Core Processes: ERP automates a multitude of routine tasks, such as generating purchase orders when inventory dips, updating financial ledgers when a sale occurs, or triggering production orders based on demand.

- Streamlining Decision-Making: With instant access to accurate, real-time data, departments can make faster, more informed decisions. This agility reduces delays and optimises business efficiency.

- Optimising Resource Utilisation: By providing a clear, real-time view of inventory, capacity, and workforce availability, ERP helps automotive manufacturers optimise the use of their assets.

Automotive Manufacturing Software - FAQ's

What ERP software is available for the automotive manufacturing industry?

ECI's M1 ERP acts as a central hub, connecting various departments and functions that might otherwise operate in isolated "silos." It provides a unified platform to automate critical information and streamline operations, including production control, supply chain management, accounting, quality, and inventory and warehouse operations.

How does M1 ERP support supply chain planning?

With a "single source of truth," M1 forecasts demand, automatically drives materials requirements (MRP), optimises supplier relationships (SRM), and enables precise production scheduling. Crucially, it offers real-time visibility into inventory and logistics, ensuring materials are available exactly when needed and products are delivered efficiently.

Can M1 ERP integrate with a MES or WMS?

Yes, M1 ERP is designed to integrate completely with ECI's Manufacturing Execution System (MES) and ECI's Warehouse Management System (WMS). This is a significant advantage for businesses considering ECI solutions, as it ensures a more cohesive and efficient manufacturing ecosystem.

Want to learn more about how our team of experts can help you?

Simply provide us your contact information, and we’ll take it from there. We can work together to help you be more competitive in the market by learning more about your business and future goals.